In the test laboratory, all routine and type tests of Extreme Power Transformers from 25 kVA to 2500 kVA are performed with our high quality test equipment. In addition, special tests are performed according to the customer's request. Our Test Laboratory aims to meet customer requests and expectations quickly and on time, to produce reliable test results based on national standards, with trained and experienced test personnel, using appropriate equipment and valid test methods under suitable ambient conditions. At the same time, in addition to protecting the confidentiality of customer information, it aims to maintain all experimental services in line with the principles of impartiality and reliability, free from any influence and pressure.

These are the tests determined as a result of mutual consultation with the customer.

- Measurement of idle current and harmonic components

- Measurement of dielectric strength and power factor of oil

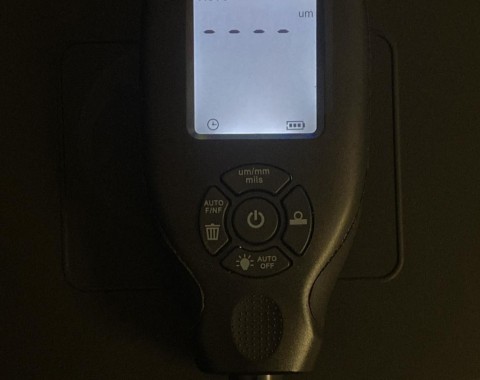

- Paint thickness and quality control test

These are the tests applied to one of the transformers of the same specification according to the customers' request.

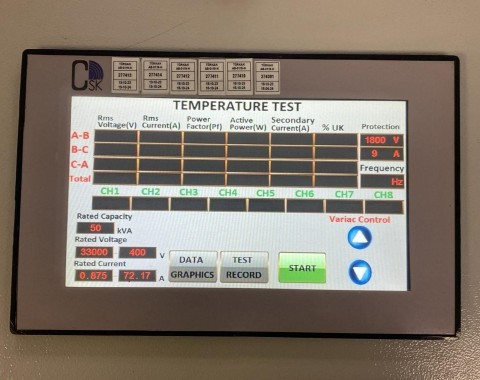

- Temperature rise test

- Lightning impact experiment

- Sound level measurement experiment

- Measurement of no-load loss and current at 90% and 10% of the rated voltage

In accordance with TS EN 60076-1 and IEC standards, the following tests are applied to each completed transformer.

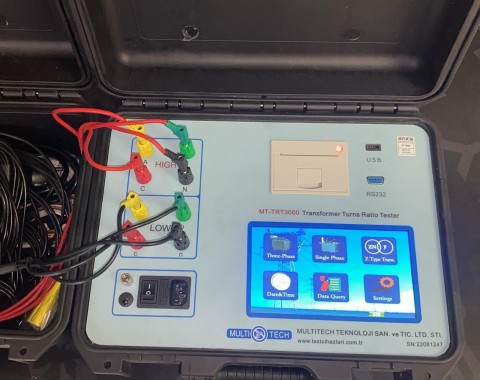

- Slew rate measurement and determination of connection group

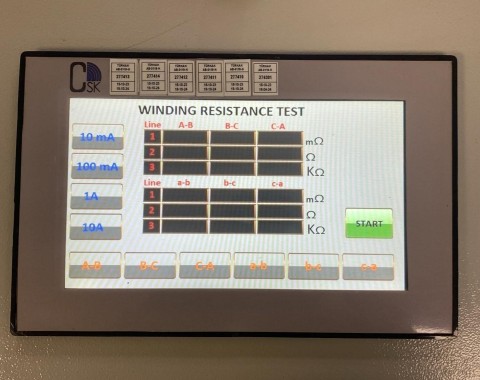

- Measurement of winding resistance

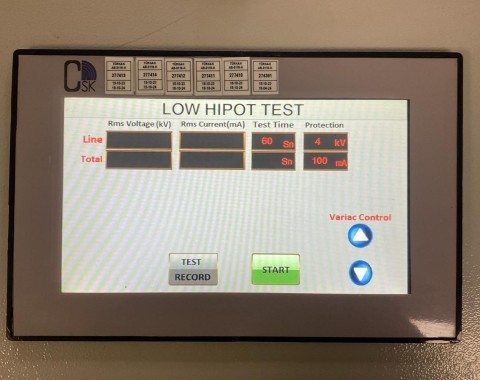

- Separately welded a.a. withstand stress test (applied stress test)

- Short-term induced a.a. voltage test (Induced voltage test)

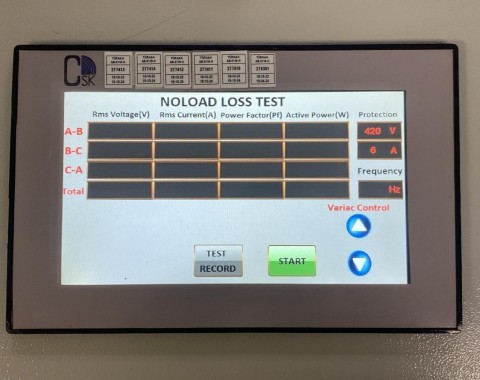

- Measurement of idle losses and idle current

- Measurement of load losses and short circuit voltage

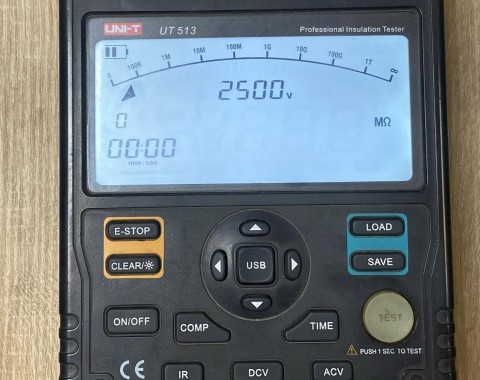

- Measurement of DC insulation resistance

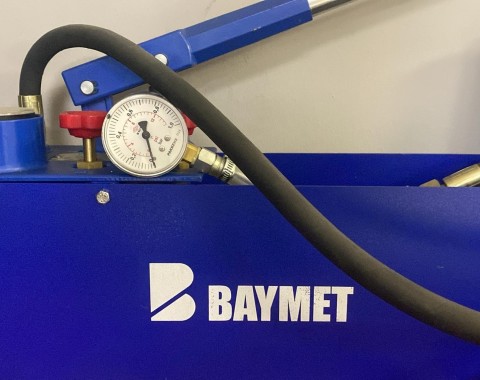

- Pressure tightness test

- Coating thickness measurement

WhatsApp Support Line